OUR PRODUCTS

Our Products

Vision Built is a company which offers significant product diversity.

Having spent several decades offering a best-in-class panelised modular solution to various markets (residential, commercial, student accommodation, life sciences) we have invested heavily in R&D to bring our first fully volumetric solutions to the market in 2021.

In effect, we have moved from a Category 2 only offering, to a company offering a tailored suite of solutions to satisfy demand for Category 1, Category 2 and Category 5 buildings. The product choice is yours and where you need product suitability assessed, we will be there to support you make the best choice for your project with a focus on driving value in terms of space and costs.

Our Process

Concept & Design

Our in house designers liaise with the clients and associated partners

to develop a detailed design for the final structure(s). Digital software

known as Revit is used to finalise the detailing, and to create a manufacturing

program for our cold form rolling machines.

Manufacture

The design program is communicated to our manufacturing team,

and manufacturing commences as per the specified schedule. Where

panels / volumetric modules are being developed, manufacturing will

occur in tandem with ground works which contributes greatly towards the

reduction of the total program duration.

Assembly

Our roll formers create track and stud specific to the project as

dictated by the software. These elements are assembled by our

factory team to create the output structures - infills, panels or volumetric

modules. Depending on the client's needs, assembly input can be

minimalist or can take the structure to an advanced stage of completion

offsite.

Installation

The completed structures are transported - over land and sea (in the

case of the UK) - and our installation team +/- partners will receive the

structures onsite and commence the erection of the final output.

Concept & Design

Our in house designers liaise with the clients and associated partners

to develop a detailed design for the final structure(s). Digital software

known as Revit is used to finalise the detailing, and to create a manufacturing

program for our cold form rolling machines.

Manufacture

The design program is communicated to our manufacturing team,

and manufacturing commences as per the specified schedule. Where

panels / volumetric modules are being developed, manufacturing will

occur in tandem with ground works which contributes greatly towards the

reduction of the total program duration.

Assembly

Our roll formers create track and stud specific to the project as

dictated by the software. These elements are assembled by our

factory team to create the output structures - infills, panels or volumetric

modules. Depending on the client's needs, assembly input can be

minimalist or can take the structure to an advanced stage of completion

offsite.

Installation

The completed structures are transported - over land and sea (in the

case of the UK) - and our installation team +/- partners will receive the

structures onsite and commence the erection of the final output.

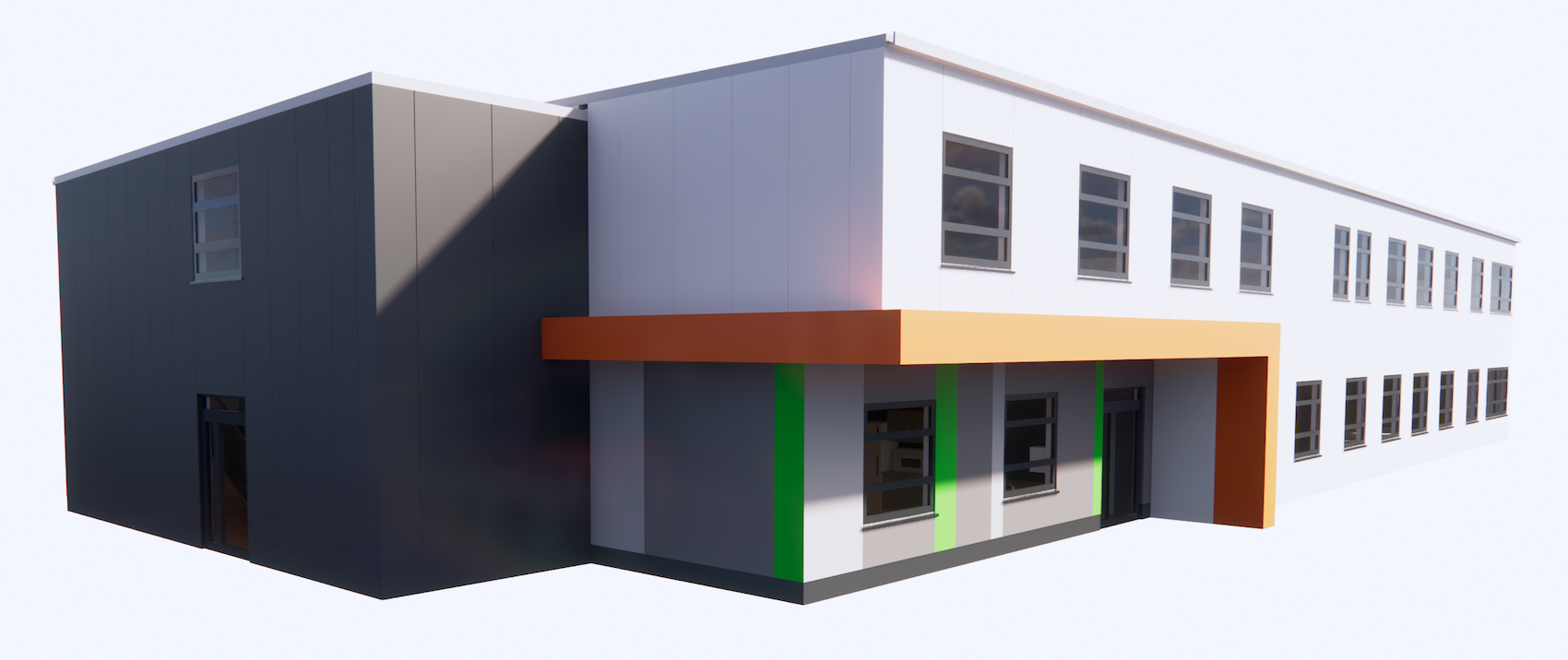

Volumetric Modular

Focused on the education and healthcare sectors, Vision Built offers

full 3D volumetric solutions using hot rolled and light gauge steel structures

manufactured by Vision Built and assembled in our state-of-the-art 100,000 sq. foot factory.

We have successfully delivered several modular projects on schedule and to spec.

Load Bearing

Structural Wall Panels

Vision Built offer a wide range of pre-assembled load bearing panels for structures up to 10 storeys. Because the panels are manufactured offsite in our factory, this reduces the amount of time and labour on site. Our external panels are delivered to site with factory applied insulation (PIR/Mineral Wool) or cement board, ready for any site applied cladding systems.

With the use of our 3D modelling software we can provide a fully integrated structure that incorporates hot rolled steel, service openings for M&E, concrete stairs or any further ancillary items.

Explore our offer in more detail...

3D Volumetric Modular Product

2D Panelised Product